For product requests contact us by using the

- Contact formular,

- Email (sales@suragus.com) or

- Phone (+49 351 32 111 520).

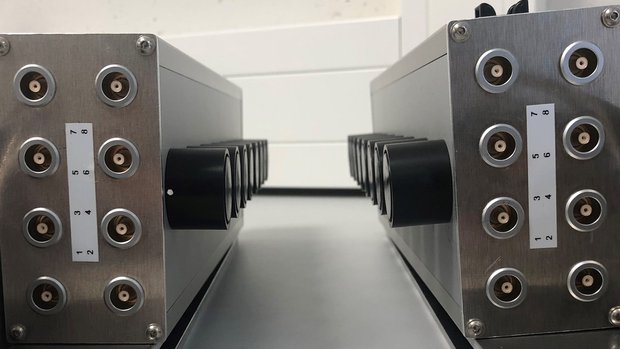

Eddy Current full-area monitoring is achieved by by use of EddyCus® inline Sensorline solution. SURAGUS provide stackable 8 Sensor Modules which allow depending on its configuration the inline monitoring on up to 128 measurement lanes

EddyCus full-area inline solutions help to monitor the entire width of small and large area coatings. This enables to track the complete product and process quality optimally. Since you can only improve things that you can measure, our solution enables you to optimize your product and process quality. This gives you a big advantage over your competitors. With our software it is easy to analyze your data perfectly. It is really simple to monitor the process and product data and let you improve your output while monitoring your product quality and process data.

The EddyCus® inline series measures layer properties such as metal layer thickness or sheet resistance in non-contact on various substrates. Typical substrates are glass, foil, paper, wafer, plastic or ceramic. Measurements are obtained by permanent measurements or by trigger events to obtain equidistant results in fast moving coating processes or measure on specific positions on small specimen. Monitoring is possible in atmosphere and in vacuum. The measurements are obtained using high samples rate and can be directly provided for process control systems and customer software. Additionally, SURAGUS offers the monitoring software EddyCus inline control that visualizes, stores and analyses metrology data.

For product requests contact us by using the