For product requests contact us by using the

- Contact formular,

- Email (sales@suragus.com) or

- Phone (+49 351 32 111 520).

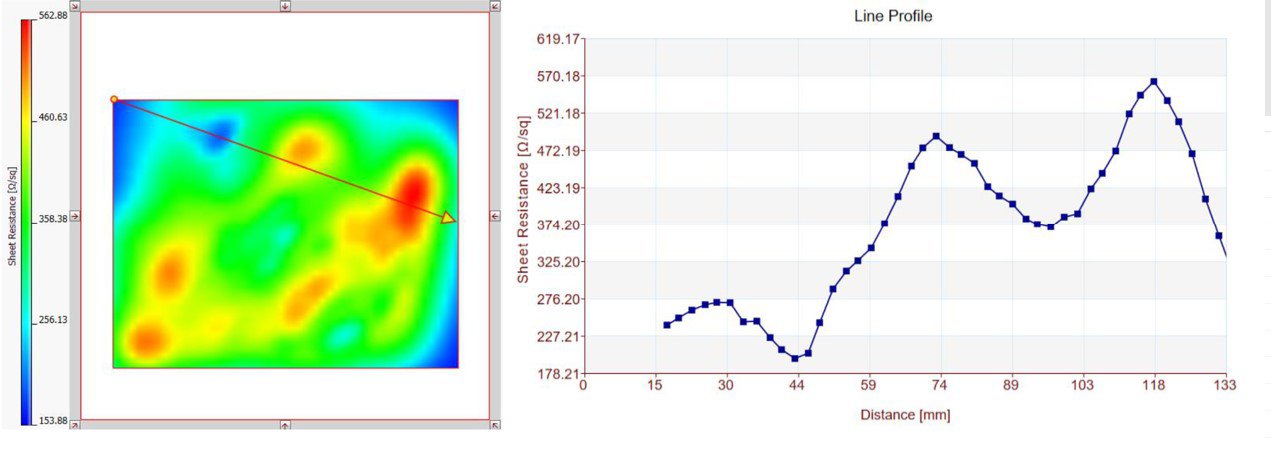

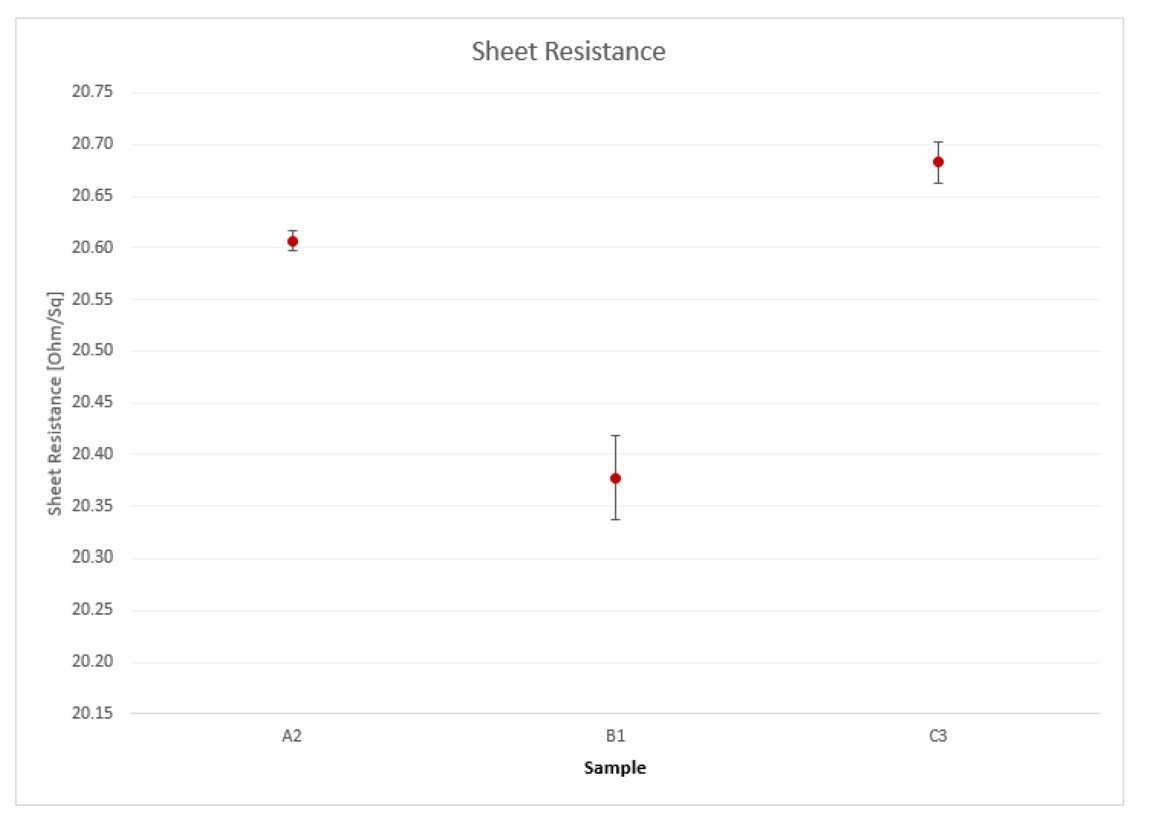

Thin film PV module manufacturer have to adress highest quality in contact and absorber layer deposition. These processes are mainly driven by physical vapour deposition (PVD) and heating cycles close to glass softening point. To ensure highest efficiency in solar module at lowest manufacturing cost following processes have to be monitored:

Organic PV cell manufacutring reqiures smooth back contact electrodes. Eddy Current Technologiy enables monitoring and quality assurence of AgNW deposition processes.

Characterizing cell integrated front contacts in a superstarte configuratioin is challenging. Eddy current technologiy utilizes anisotropic properties to separate the electromagnetic field of the front contact from the electromagnetic field of the back contact. Hence, sheet resistance of cell integrated front contact of a manufacutred thin film PV mdoule can be characterized.

For characterization of deposition processes in thin film photovoltaic SURAGUS refers to the following products:

For product requests contact us by using the