For product requests contact us by using the

- Contact formular,

- Email (sales@suragus.com) or

- Phone (+49 351 32 111 520).

High frequency eddy current measurement devices can be used not only for characterizing conductivity and magnetic permeability related properties of electrically conductive materials, but also for permittivity characterization of insulators. This is based on the fact that eddy current systems generate electric and magnetic fields, where the electric field distribution is affected by the permitivity within the generated fields. This effect can be used for non-contact permittivity characterization. Applications include

SURAGUS offers single point, imaging tools and inline sensors for high frequency characterization. Especially the inline permittivity measurement by high frequency impedance analysis is beneficial

SURAGUS offers various sensor types, often customized towards the measurement task that are mostly dedicated for testing on flat substrates or to characterize liquids, powders and other substances in pipes or specific containers. Please feel free to contact our team for discussion of specific testing tasks.

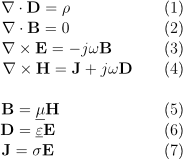

Maxwell’s equations for constant frequencies (1 - 4) suggest that sample conductivity and permittivity influence the eddy current coil impedance. Here a magnetic field H with the magnetic flux density B, varying in time with the angular frequency ω generates a rotating electric field E independent of the conductivity of the sample (3). The current density J depends on the conductivity of the sample σ (7), whereas the displacement current density JD depends on the permittivity ε of the material to be tested (6). This effect is not relevant for traditional low frequency eddy current testing solutions but becomes visible with high frequency testing systems. Research and studies using SURAGUS EddyCus high frequency eddy currents systems have be published and peer reviewed for some applications. (cf. S. Gäbler, H. Heuer and G. Heinrich, "Measuring and Imaging Permittivity of Insulators Using High-Frequency Eddy-Current Devices," in IEEE Transactions on Instrumentation and Measurement, vol. 64, no. 8, pp. 2227-2238, Aug. 2015, doi: 10.1109/TIM.2015.2390851. )

Permittivity, is known as a dielectric constant. Permittivity describes the relative ability of a dielectric to store electrostatic energy in an electric field. The smaller the relative dielectric constant of materials, the better the insulation. When a medium is applied with an electric field, the induced charge will be generated to weaken the electric field. The ratio of the original applied electric field (in vacuum) to the final electric field is called permittivity, which is also related to the frequency.

The advent of the high-tech era has led to changes and demands for high-tech materials, and the emergence of new technologies has created new performance requirements for materials, including microwave dielectric ceramics, PCB materials, semiconductor materials, mobile phone antenna materials, mobile phone shell materials, electromagnetic shielding materials and dielectric materials, etc. will all change in high-tech applications. This requires higher electromagnetic wave transmission speed and lower signal propagation losses, which means higher dielectric constants and lower dielectric losses of the materials used in the application. Dielectric materials meet these exacting requirements.

The standard SI unit for permittivity is Farad per meter (F/m or F·m-1) . The permittivity in vacuum is called vacuum permittivity ε0, ε0 ≈ 8.854187817…×10⁻¹² F/m. The permittivity is often represented by the relative permittivity εr, which is the ratio of the absolute permittivity ε and the vacuum permittivity ε0.

There are many methods developed for measuring permittivity or dielectric constant, and each one of them can be conducted to certain frequencies, materials, applications and etc..

| Methods | Applicable Scenarios | Advantages | Limits |

|---|---|---|---|

| Open-ended coaxial probe | Liquids, biological, specimen, semi-solids | easy to operate | due to low f, not suitable for complex electronics |

| Transmission Line | mostly applied to test low- and medium loss material with large εr | high accuracy, any frequencies | multi-value problem, request on shape and size, low accuracy on thin film and rough surface |

| Resonant method | good performance in 1GHz - 10GHz, suitable for lowloss material | good accuracy, easy to operate | Inaccurate in loss tangent, multi error sources |

| Free space | good performance in 3GHz - 100GHz | No direct contact needed, wide measurement range | errors caused by standing waves |

Open ended coaxial probe method has been used for years as a non-destructive testing method. In this method the probe is pressed against a specimen or immersed into the liquids and the reflection coefficient is measured and used to determine the permittivity.

Transmission line method is a popular broadband measurement method. In the method, only the fundamental waveguide mode (TEM mode in coaxial line and TE mode in waveguides) is assumed to propagate. Calibration must be carried out before making measurement.

Resonant method provides high accuracies and assumes the TE or TM propagation mode. Resonant measurements are the most accurate methods of obtaining permittivity and permeability. However, there are limitations on the frequencies and loss characteristics

of the materials that can be measured with the method.

Free space method is for broadband applications and assumed only the TEM propagation mode. Free space measurement allows measurements on material under test (MUT) under high temperatures or hostile environments and generally operates in wide band frequencies.

Industry is applying the following methods in laboratories:

Dielectric Analysis (DEA) or dielectric cure monitoring is a thermal analysis technique for determining cure state. DEA tracks the cure state of a material by measuring the electrical properties of permittivity. Permittivity (ε) is related to energy storage in a material.

Differential scanning calorimetry (DSC), one method for studying polymers, like measuring glass transition temperature Tg, which changes with cure state.

Dielectric thermal analysis (DETA) is the process by which analyze the material by measuring the dielectric coefficient, and dielectric loss of a specimen under an alternating electric field as a function of temperature, frequency or time, to evaluate physical and chemical change in the material.

The quality assurance and process control of the following applications can be supported permittivity measurements:

| Substance | Dielectric Constant |

|---|---|

| Acetal | 3,8 |

| Acetaldehyde | 15 |

| Acetamide | 59,2 |

| Acetoacetic acid ethyl ester | 15 |

| Acetone | 21,5 |

| Acetophenone | 18 |

| Acetylacetone | 23 |

| Acetyl bromide | 16,2 |

| Acetyl chloride | 15,9 |

| Acetylene dibromide | 7,2 |

| Acetylene tetrabromide | 5,6 |

| Aconite acid ester | 6,3 |

| Adipic Acid | 1,8 |

| Aerosile | 1 |

| Activated carbon | 12 |

| Alum | 4,2 |

| Allyl alcohol | 20,6 |

| Allyl chloride | 8,2 |

| Allyl iodide | 6,1 |

| Aluminium bromide | 3,4 |

| Aluminium foil | 10,8 |

| Aluminium hydroxide | 2,5 |

| Aluminium splinters | 7,3 |

| Aluminium sulfate | 2,6 |

| Triethylaluminium | 2,9 |

| Formic acid | 57,9 |

| Ammonia | 15 |

| Ammonia solution (25%) | 31,6 |

| Ammonia salt | 4,3 |

| Pentanol | 14,8 |

| Amyl amine | 4,5 |

| Aniline | 7 |

| Anisealdehyde | 22,3 |

| Anisole | 4,5 |

| Anthracite/hard coal | 3,2 |

| Antimony hydride | 1,8 |

| Malic acid diethylester | 10 |

| Argon | 1,5 |

| Arsine | 2,1 |

| Arsole | 2,3 |

| Asbestos | 10 |

| Ascorbic acid (vitamin C) | 2,1 |

| Azelaic acid diethylester | 5 |

| Azoxybenzene | 5,2 |

| Basalt | 2,5 |

| Cotton fibre flour | 3,2 |

| Bauxite | 2,5 |

| Bentonite | 8,1 |

| Benzal chloride | 6,9 |

| Benzaldehyd | 17,6 |

| Benzil (80°C) | 10 |

| Gas | 2 |

| Benzene | 2,3 |

| Benzene, heavy | 3,2 |

| Benzyl alcohol | 13,5 |

| Benzyl^amine | 4,6 |

| Benzyl chloride | 7 |

| Beer brew | 25 |

| Bitumen | 2,8 |

| Hydrogen cyanide | 158 |

| Bore oil emulsion | 25 |

| Bornylacetat | 4,6 |

| Bromine | 3,1 |

| Butanoic acid | 3 |

| Camphene | 2,3 |

| Caproic acid | 2,6 |

| Caprylic acid | 2,5 |

| Carbazole | 1,3 |

| Carbonylcyanid | 10,7 |

| Cellit | 1,6 |

| Cetyl alcohol (60°C) | 3,6 |

| Quinoline | 8,8 |

| Chlor, fluid | 2,1 |

| Chloral | 6,7 |

| Chlor benzene | 5,7 |

| Chloroacetic acid | 33,4 |

| Chloorhydrin | 31 |

| Chlorinated lime | 2,3 |

| Chloroform (trichlormethane) | 4,8 |

| Cola essence | 17,3 |

| Cream (skin) | 19 |

| Cuminaldehyde | 10,7 |

| Cyanogen | 2,5 |

| Decalin | 2,1 |

| Degalan | 3,1 |

| Desmodur | 10 |

| Diacetone alcohol | 18,2 |

| Diamylether | 3 |

| Dibenzofuran (100°C) | 3 |

| Dibenzyl (60°C) | 2,5 |

| Diesel Fuel | 2,1 |

| Diethylamine | 3,8 |

| Dimethylether (methyl ether) | 5 |

| Diofan | 32 |

| Dioxane | 2 |

| Diphenyl | 2,5 |

| Printing ink | 4,6 |

| Ice cream | 16,5 |

| Iron(III)oxide red | 1,9 |

| Emulphor | 4 |

| Epichlorhydrin | 23 |

| Peanuts, dried | 3,1 |

| Peatnut expeller | 2,4 |

| Vinegar | 24 |

| Acetic acid | 6,2 |

| Cement asbestos | 3,2 |

| Ethanol (ethyl alkohol) | 16,2 |

| Aether | 4 |

| Ethayl acetate | 6 |

| Ethylamine | 6,9 |

| Ethyl benzoate | 6 |

| Ethyl benzene | 2,4 |

| Ethylene chlorhydrin | 25 |

| Ethylene chloride | 10,6 |

| Ethylenediamine | 15 |

| Etylene oxide | 13,9 |

| Ethyl mercaptan | 6,9 |

| Fenchone | 12,8 |

| Ferrite pellets | 21 |

| Ferrosilicon | 10 |

| Green vitriol | 32,4 |

| Ferrozell | 18,3 |

| Fat coal | 3,4 |

| Fatty acid | 1,7 |

| Fish oil | 2,6 |

| Flax pellets | 1,4 |

| Meat and bone meal | 1,9 |

| Tankage | 1,9 |

| Fly ash | 3,3 |

| Fluorine | 1,5 |

| Fluorbenzene | 6,4 |

| Hydrogen Fluoride | 83,6 |

| Calcium fluoride | 2,5 |

| Formamide | 109 |

| Furan | 3 |

| Furfurol | 41,7 |

| Animal feed grist | 2,4 |

| Germanium tetrachloride | 2,4 |

| Grain grist | 3 |

| Gypsum | 1,8 |

| Fiber glass powder | 1,1 |

| Glass granulate | 4 |

| Cullet | 2 |

| Glucose (50%) | 30 |

| Glycerol | 13,2 |

| Glycerol water | 37 |

| Glycol | 37 |

| Glysantin | 25 |

| Granuform | 4 |

| Guaiacol | 11 |

| Guano | 2,5 |

| Oat | 4,9 |

| Urea | 2,9 |

| Resin | 1,5 |

| Hazels | 2 |

| Hot glue | 2,3 |

| Heating oil | 2,1 |

| Helium | 1,1 |

| Heptane | 1,9 |

| Heptanal | 9,1 |

| Heptanoic acid | 2,6 |

| Heptene | 2,1 |

| Hexane | 1,9 |

| Hexene | 2,1 |

| Hexanol | 12,5 |

| Hibiscus | 2,8 |

| Wood chips | 2,3 |

| Charcoal | 1,3 |

| Wood swarf | 1,5 |

| Splints | 1,1 |

| Honey | 24 |

| Hydrazine | 58 |

| Imidazole, pure | 23 |

| Isoamyl acetate | 4,8 |

| Isoamyl alcohol | 15,6 |

| Isoamyl bromide | 6 |

| Isoamyl chloride | 6,1 |

| Isoamyl ether | 2,8 |

| Isoamyl iodide | 5,6 |

| Isobutanoic acid | 2,6 |

| Isobutyl alcohol | 18,1 |

| Isobutyl amine | 4,4 |

| Isobutyl benzene | 2,3 |

| Isobutyl bromide | 7,2 |

| Isobutyl chloride | 6,5 |

| Isobutyl cyanide | 18 |

| Isobutyl iodide | 6,5 |

| Isobutyl nitrate | 11,7 |

| Isobutyl silane | 2,5 |

| Isoquinoline | 10,7 |

| Isocyanate | 6,1 |

| Isoprene | 2,1 |

| Isopropanol | 18 |

| Isosafrol | 3,3 |

| Iodine | 11,1 |

| Iodobenzene | 4,6 |

| Methyl iodide | 7,1 |

| Hydrogen iodide | 2,9 |

| Coffee beans | 1,5 |

| Cacao beans | 1,8 |

| Caustic potash | 3,3 |

| Potash salt | 2 |

| Lime | 2 |

| Potato starch | 1,7 |

| Ceramic compound | 17 |

| Ketchup | 24 |

| Gravel | 2,6 |

| Diatomaceous earth | 1,4 |

| Silicic acid | 2 |

| Bone fat | 2,7 |

| Bonemeal | 1,7 |

| Sodium chloride | 23 |

| Coal, 15 % moisture | 4 |

| Diethyl carbonate | 2,8 |

| Coal dust | 2,5 |

| Coconut oil (refined) | 2,9 |

| Coke | 3 |

| Cork powder | 1,7 |

| Concentrated feed | 3,2 |

| Chalk | 2,1 |

| Cresol | 11 |

| Cresol resin | 18,3 |

| Crystal sugar | 2 |

| Fertiliser | 4,3 |

| Plastic pellets | 1,2 |

| Copper ore | 5,6 |

| Lanolin | 4,2 |

| Latex | 24 |

| Lauric acid ethyl ester | 3,4 |

| Glue | 2 |

| Linoleic acid | 2,7 |

| Solvent | 18 |

| Laughing gas | 1,5 |

| Skim milk powder | 2,3 |

| Corn | 3,6 |

| Corn grist | 2,1 |

| Corn starch sirup | 18,4 |

| Malt | 2,7 |

| Mandelic acid nitril | 18 |

| Marble stones small (2-3 mm) | 2,5 |

| Mice feed | 2,3 |

| Flour | 2,5 |

| Molasses | 31,3 |

| Menthol | 4 |

| Mesityl oxide | 15 |

| Metal powder | 6 |

| Methanol (methyl alkohol) | 33 |

| Methyl acetate | 8 |

| Methylene bromide | 7 |

| Methylene chloride | 9 |

| Methylene chloride | 9,1 |

| Metylene iodide | 5,3 |

| Methyl nitrate | 23,5 |

| Methyl cellulose | 3 |

| Mono chlormethane | 9,8 |

| Morpholine | 7,3 |

| Naphthenic acid | 2,6 |

| Naphtalene | 2,5 |

| Soda | 3 |

| Sodium methylate | 1,5 |

| Sodium perborate | 2,2 |

| Sodium peroxide | 2,7 |

| Sodium sulfate | 2,7 |

| Nitrobenzene | 35 |

| Nitroethane | 29 |

| Nitroglycol | 28,3 |

| Nitroglycerin | 19,3 |

| Nitro varnish | 5,2 |

| Nitromethane | 39 |

| Nitro phoska | 5,4 |

| Nitrosyl bromide | 15,2 |

| Nitrosyl chloride | 19 |

| Pasta | 1,9 |

| Octane | 2 |

| Octene | 2,1 |

| Octyl bromide | 5 |

| Oil | 2 |

| Oleic acid | 2,5 |

| Water-in-oil-emulsion | 24,2 |

| Oxalo ethyl acetate | 6 |

| Palm tree nut | 2,2 |

| Palmitic acid | 2,3 |

| Palm nut/kernel/seed | 2,8 |

| Palm seed oil | 1,8 |

| Paper scraps | 1,2 |

| Paraffin | 1,6 |

| Paraldehyde | 15,1 |

| Pelargon | 2,8 |

| Penta borane | 21 |

| Penta ethyl chloride | 3,8 |

| Penta chlortoluene | 4,8 |

| Pentane | 1,8 |

| Pentanal | 11,8 |

| Pentene | 2 |

| Perchlorate | 3,6 |

| Hexachlorobutadiene | 2,6 |

| Perlite | 1,7 |

| PET powder | 1,5 |

| Phenetole | 4,2 |

| Phenol | 8 |

| Phenol resin | 7,4 |

| Phosgene | 4,3 |

| Phosphate | 4 |

| Phosphorus, liquid | 3,9 |

| Phosphorus salt | 4 |

| Pinane | 2,1 |

| Piperidine | 5,8 |

| Polyamide pellets | 1,7 |

| Polyethylene | 1,2 |

| Polypropylene | 1,6 |

| Polyrol | 2,8 |

| Polyvinyl acetals | 2,8 |

| Popcorn | 1,1 |

| Pril | 1,2 |

| Propionaldehyde | 14,4 |

| Propanoic acid | 3,2 |

| Propanol (propyl alcohol) | 2,2 |

| Propylamine | 3 |

| Propylene, liquid | 1,9 |

| Propylene chloride | 9 |

| Propylether | 3,3 |

| PVC powder, pure | 1,3 |

| Pyridine | 13,2 |

| Pyrroles | 8 |

| Silica sand | 2 |

| Quartz stone meal | 2,7 |

| Mercury diethyl | 2,1 |

| Rapeseed | 3,3 |

| Rapeseed grist | 2,1 |

| Rice | 3 |

| Rye | 6 |

| Rye bran | 2,2 |

| Beets seeds | 3,5 |

| Beets cuttings | 7,3 |

| Carbon black | 18,8 |

| Saccharose solution | 20 |

| Sawdust | 1,3 |

| Nitric acid (98%) | 19 |

| Hydrochloric acid | 5 |

| Salt water | 32 |

| Oxygen | 1,5 |

| Chamotte | 1,8 |

| Foam flakes | 1,1 |

| Lard (80°C) | 2,1 |

| Soft soap | 32 |

| Chocolate powder | 2 |

| Black liquor | 32 |

| Sulphur | 3,5 |

| Sulphur dioxide | 14 |

| Carbon disulphide | 2,6 |

| Sulfuric acide | 21,9 |

| Sulfuric acide (17%) | 31 |

| Sulfuric acide (97%) | 8,6 |

| Sulfur trioxide | 3,1 |

| Hydrogen sulfide | 6 |

| Heavy fuel oil | 2,2 |

| Soap flakes | 9,2 |

| Soap pellets | 3,5 |

| Mustard | 24 |

| Grain of mustard seed | 3,6 |

| Silicone oil | 2,7 |

| Silicone rubber | 2,9 |

| Soy flour | 4,5 |

| Grain of soy | 2,9 |

| Sunflower seeds | 2 |

| Chaff | 1,5 |

| Stearic acid | 2,3 |

| Rock salt (0-25 mm) | 4,3 |

| Styrene | 2,4 |

| Tobacco dust | 1,8 |

| Talcum | 1,5 |

| Tea powder | 2 |

| Tar | 4 |

| Terephthalic acid | 1,5 |

| White spirit | 2 |

| Terpinene | 2,7 |

| Terpinolene | 2,3 |

| Tetrachlorethylene | 2,5 |

| Carbon tetrachloride | 2,3 |

| Thomaskali dust | 3,4 |

| Thujone (0°C) | 10,8 |

| Meat and bone meal | 2,2 |

| Titan tetrachloride | 2,8 |

| Toluene | 2,4 |

| Clay | 2,3 |

| Transformer oil | 2,1 |

| Trichloroethylene | 3,2 |

| Triptan | 1,9 |

| Dry yeast | 2 |

| Ultrasil | 1,4 |

| Undecan | 2 |

| Valeric acid | 2,7 |

| Viscose | 34,5 |

| Wax | 1,8 |

| Benzine | 2 |

| Water | 80,3 |

| Water (360°C) | 10 |

| Water, demineralisiert | 29,3 |

| Water, heavy | 78,3 |

| Sodium silicate | 16 |

| Hydrogen | 1,2 |

| Hydrogen peroxide | 84,2 |

| Wine | 25 |

| Tartaric acid | 35,9 |

| Wheat | 4 |

| Wheat starch | 2,5 |

| Xylitol | 40 |

| Xylene | 2,3 |

| Tooth paste | 18,3 |

| Cellulose | 1,2 |

| Cement | 2,2 |

| Zinc oxide | 1,5 |

| Zinc powder | 4,4 |

| Sugar | 1,8 |

| Tinder | 12 |

For product requests contact us by using the